Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Material: Carbon Steel,Stainless Steel,Steel Alloy,Brass,Bronze,Ect.

Use: The Door Components

Surface Treatment: Plating,Powder Coating,Hot Galvanized,Ect.

Heat Treatment: According To The Clients' Requirements

Packaging: bubble bags,carton,pallets,and other packages as the clients' required

Transportation: Ocean,Land,Air,by train

Place of Origin: Zhejiang Province,China

Certificate: ISO9001:2015;TS16949

HS Code: 8481901000

Port: NINGBO,SHANGHAI,NINGBO

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

the carbon steel Investment Casting parts of the door component

connecting piece for door hardware

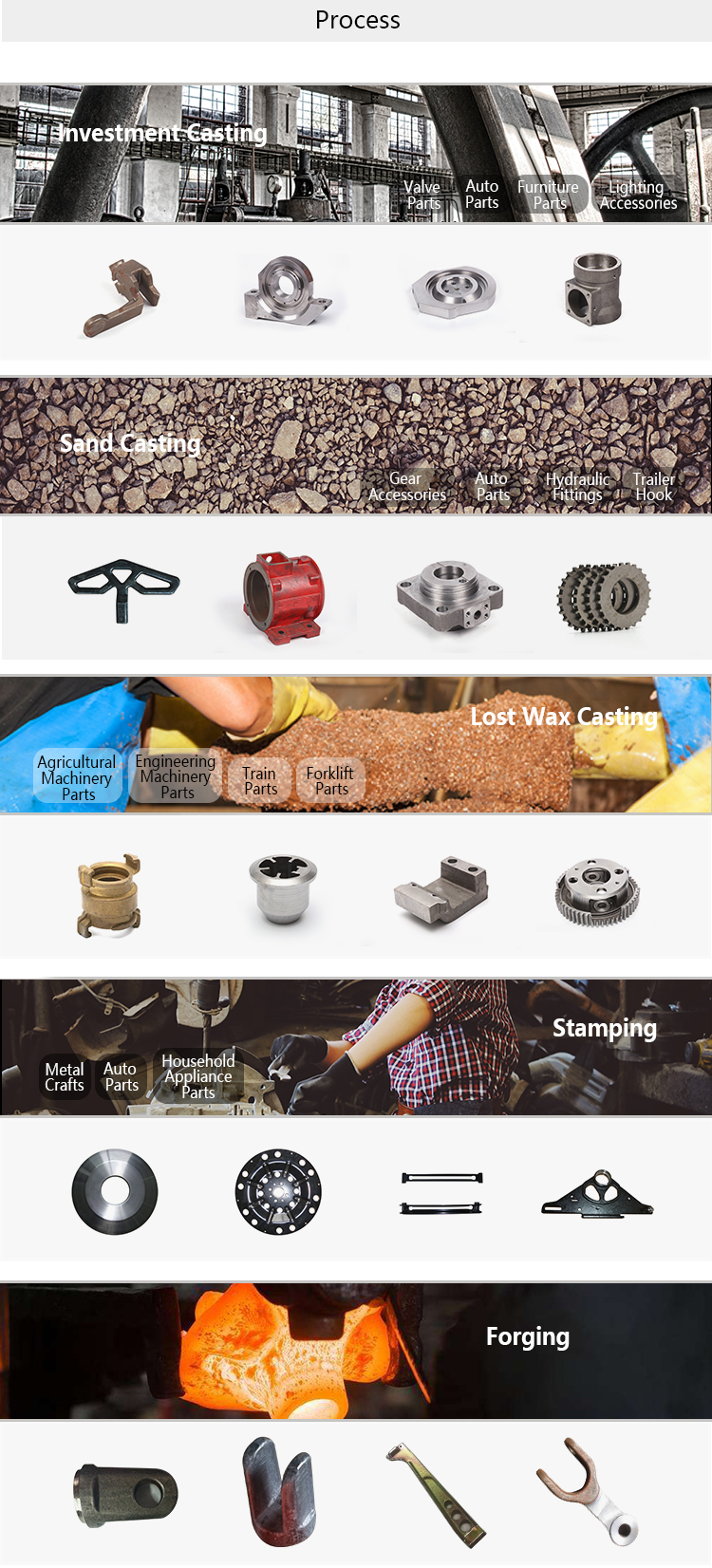

Lost Wax Casting & CNC MACHINING

Machining Equipment:

CNC Machining Center, CNC Lathes, CNC Milling Machine, Linear cutting machine ,grinding machine ,etc.

Packaging:

1) Polybag and carton, 0.5-10 kg/carton,

2) Pallet or container

3) As per customized specifications.

What kinds of products can we offer?

| Products | According to the customers'technical drawings or s amples | |||||

| Casting Material | Cast Iron, ductile iron, Grey iron, GG25, GG20, GGG40, GGG50, GGG60 GGG70: | |||||

| QT400-18,QT450-10,0T600-3QT700-2,FCD400,FCD450,60-40-18,65-45-12,ect. | ||||||

| Casting Product Weight | available from 0.02kg to 3000kg | |||||

| Surface Treatment | Oxidation | |||||

| Plating zinc | ||||||

| Painting | ||||||

| Hot galvanized | ||||||

| Powder coating | ||||||

| Electroplating | ||||||

| Sand blasting | ||||||

| Electrophoresis | ||||||

| Vbration Grinding | ||||||

| Inspection | *100% ins pection before shipping, offer the material reports and mechanical property reports | |||||

| *Control Plan and PPAP documents according to the clients'requirements | ||||||

| *ISO9001: 2015 quality control system | ||||||

| Extra Service | CNC machining servce in our machining workshop | |||||

| Advantages | * The dimensions and outs ide shape are similar with investment casting | |||||

| *The surface roughness is good from 2.5 to 25um(100 to 1000um | ||||||

| *The min thickness can meet 3 mm(0. 120inch) | ||||||

| *decrease the internal crack and keep close structure | ||||||

| *As no joint and defect the cleaning and machining work can be less | ||||||

| *it's cheaper because its a simpler process and the foam is cheaper than the wax | ||||||

Product Categories : Lost Wax Casting

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.